Print a nozzle check pattern and check whether there are discharge defects such as nozzle clogging (blurring or drop-out of printing).

You cannot print a test pattern on narrow media. When performing test printing, use media that has a width of 420 mm (approx. 16.5 inches) or more.

When using roll media, rewind the roll media and make sure there is no warping before printing. Failure to do so may cause defects in image quality.

Never open the middle cover or raise the lever during printing. Opening the cover or raising the lever will abort printing.

- Check that the media is set.

- Change the print origin.

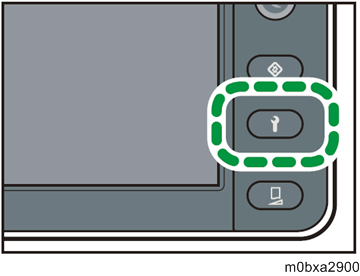

For details, see "Changing Print Origin", Operating Instructions. - Press the [Maintenance] key.

- Press [Print Test].

- Press [Execute].

- Check the printed result of the nozzle check. (How to Read the Printing Result)

- If problems occur, perform head cleaning. (Performing Head Cleaning)

Press [End].

It is not reflected in the result of the test print even when [Nozzle Recovery] is set to [ON]. When checking the print result in which the clogged nozzle is recovered, print a recovery check pattern by using the RIP software. For details, see "Functions on the Main Menu", RIP Setting Guide.