This machine employs the dual tank mechanism. Dual tank mechanism requires supply paths between the ink cartridges and head tanks but has the advantage of lightweight carriage unit and high-capacity ink cartridges.

In the damper, there is a liquid room for each row of nozzles. Ink is supplied as required from the supply port at the top of the head tank and then supplied to the print head with constant pressure.

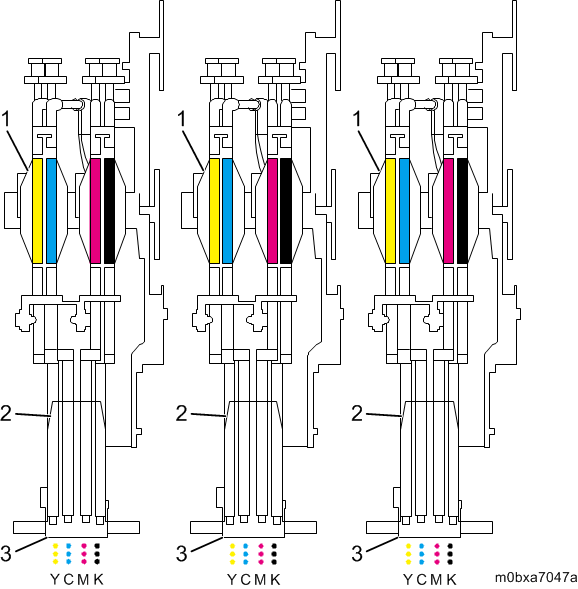

Example: 4C machine

| No. | Name | Q'ty |

|---|---|---|

1 | Damper | 12 |

2 | Print Head Unit | 3 |

3 | Print Head | 12 |

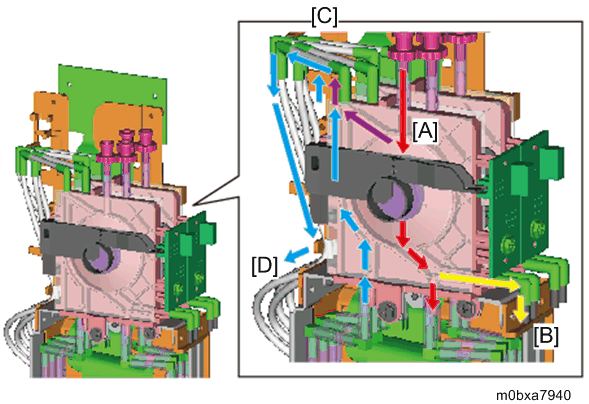

Ink Supply Path (between Damper and Print Head)

Ink that has been supplied to the damper via the supply port [A] is transported to the head through the path indicated by the red arrows. When white ink is circulated, it is transported to the circulation path through the path indicated by the yellow arrows.

Air inside the damper is exhausted from the exhaust port [C] through the path indicated by the blue arrows. Air that has gotten inside the damper - print head path is exhausted together with the ink through the path indicated by purple arrows.

Air purge is done when the air purge port [D] is manually opened and the ink supply pump is driven. Air is transported through the exhaust port [C] and is purged through the air purge port [D] together with the ink.

* The arrows indicate the paths for ink and air.

| Arrow | Path | Arrow | Path |

|---|---|---|---|

| Ink supply path |  | Air purge path (air inside damper) |

| White ink circulation path |  | Air purge path (air inside damper) |

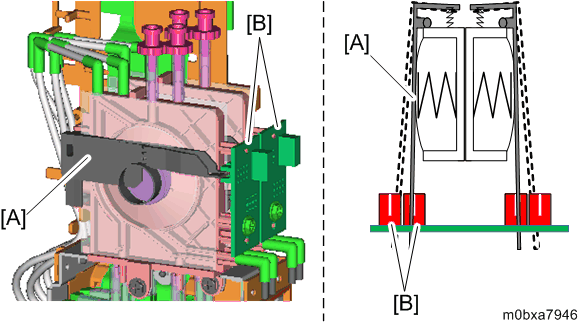

OCFS (On Carriage Feeler Sensor)

Ink is constantly supplied under the ink supply system of this machine. Because of this, the dampers are equipped with the on carriage feeler sensors (OCFSs) [B] that detect the ink full detection feeler. The feeler [A] moves as the ink in the damper increases or decreases and the amount of ink is monitored by detecting the feeler position with the two OCFSs [B]. This enables the machine to control the amount of ink in the damper through supply and consumption of ink even during printing. Keeping the amount of ink in the damper at an appropriate level enables fast continuous printing on wide paper.

Ink supply control

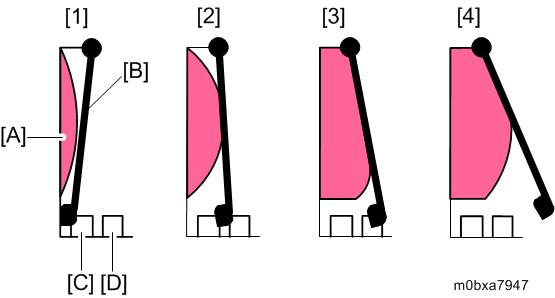

The condition of ink [A] inside the damper is monitored by the two OCFSs [C] [D] which detect the position of the ink full detection feeler [B]. The machine controls ink supply in four steps as follows.

| Ink condition | OCFS | Damper condition | Ink supply control | |

|---|---|---|---|---|

| Inner [C] | Outer [D] | |||

[1] Low | ON | OFF | Ink supply is required. | Ink is supplied. |

[2] Mode | ON | ON | Ink supply is required. | Ink is supplied. |

[3] Full | OFF | ON | Normal | Ink supply is stopped after a predetermined time. |

| [4] Limit | OFF | OFF | Overflow | Ink supply is stopped immediately. |