The roll feed unit feeds the roll paper set to the roll holder. The winding unit rolls up roll paper to the roll core set to the roll core holder after printing.

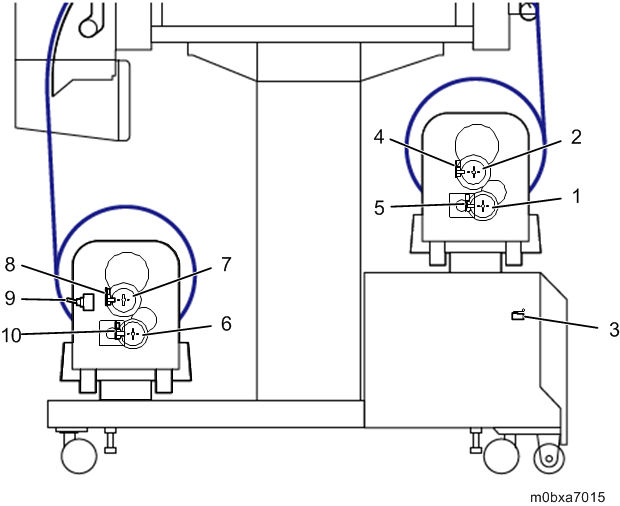

| No. | Name | No. | Name |

|---|---|---|---|

| 1 | Paper Feed Encoder | 6 | Roll-up Encoder |

| 2 | Roll Paper Residual Amount Encoder | 7 | Take-up Unit Rotary Encoder |

| 3 | Roll Feed Unit Set Switch | 8 | Take-up Unit Rotary Encoder |

| 4 | Roll Paper Residual Amount Encoder Sensor | 9 | Roll-up Switch |

| 5 | Paper Feed Encoder Sensor | 10 | Roll-up Encoder |

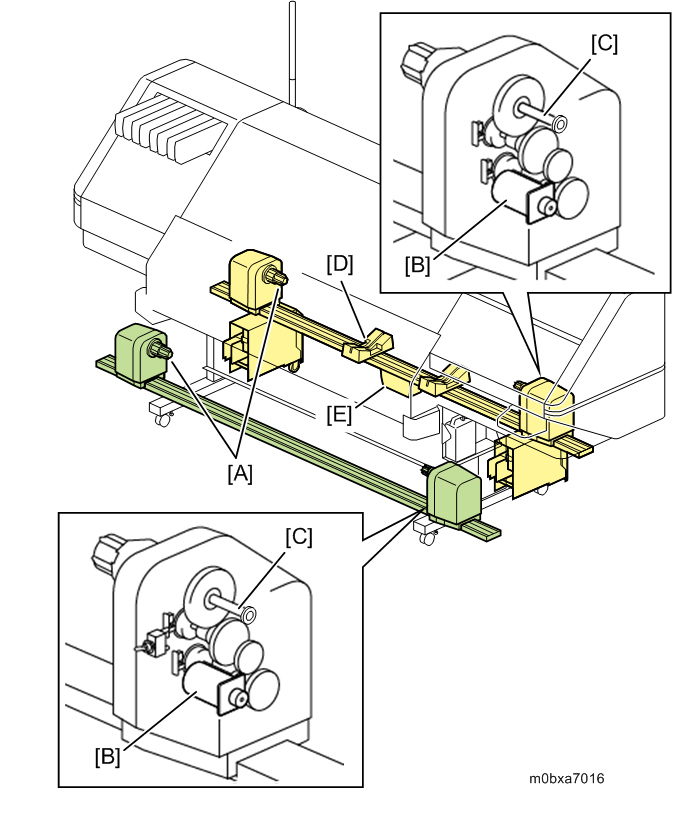

Basic Component

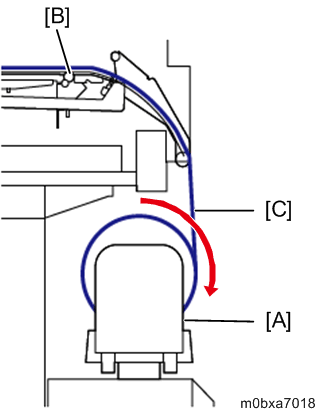

The configuration is common to the roll feed unit and the winding unit. Either the roll paper or the roll core is set to the roll holder/roll core holder [A] at both sides of the unit. The drive motor [B] rotates the roll core holder shaft [C] to feed/wind paper. The media bench [D] can be used for temporarily placing the roll paper when setting it.

Only the roll feed unit is equipped with the drawer lever [E] which enables the user to draw out the unit when replacing roll paper.

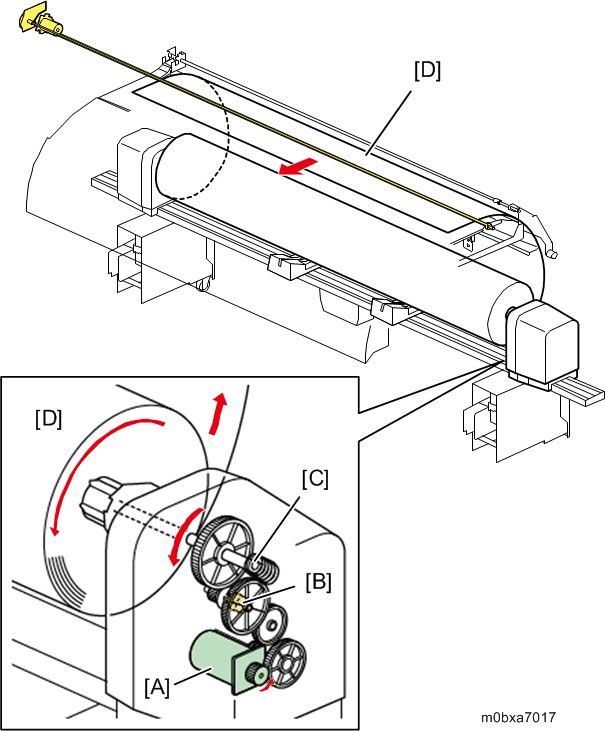

Roll Paper Feed Drive

The roll feed unit is equipped with the paper feed motor [A] which rotates the roll core holder shaft [C] via the torque limiter [B] to transport roll paper. Have the fed roll paper arrive at the registration roller [D] by hand.

The machine's paper feed motor rotates in reverse direction when transporting paper to rewind it. This puts tension on the roll paper [C] between the roll feed unit [A] and the registration roller [B], preventing the slack of paper.

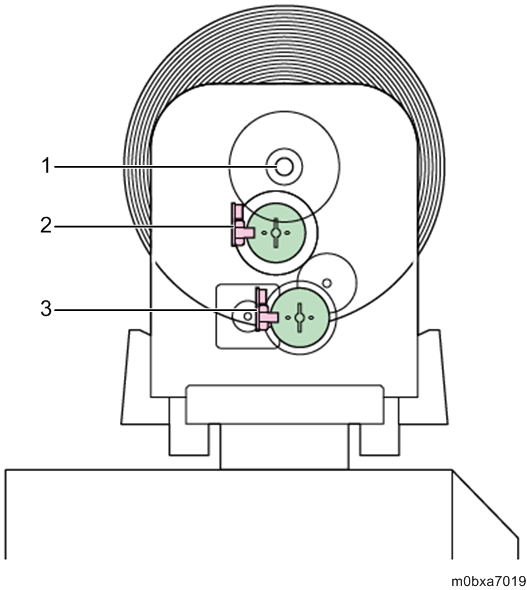

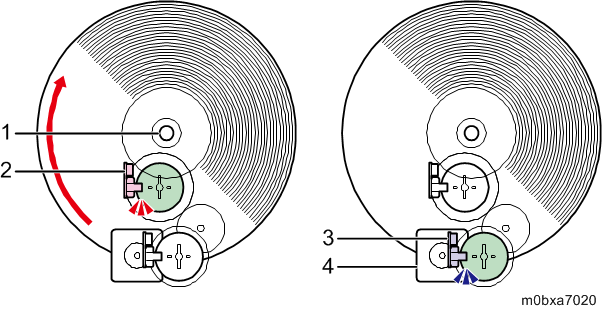

Remaining Paper Detection, Paper Feed Motor Rotation Detection

The amount of remaining roll paper is detected by calculating the outside diameter of the roll based on the number of rotations of the roll core holder shaft which is detected by the roll paper residual amount encoder sensor from the encoder.

| No. | Name | No. | Name |

|---|---|---|---|

| 1 | Flange shaft | 3 | Paper Feed Encoder Sensor |

| 2 | Roll Paper Residual Amount Encoder Sensor |

The amount of remaining roll paper is measured at the following timings.

- Initialization after the roll paper is set

It is measured when the carriage unit moves forward and performs skew detection. - Intermittent operation during printing and drying after printing

It is measured at the start of intermittent drive after each time paper is transported 80 mm.

The paper feed encoder sensor checks the operation and number of rotations of the motor.

| No. | Name | No. | Name |

|---|---|---|---|

| [A] | Roll paper residual amount detection | [B] | Motor rotation detection |

| 1 | Flange Shaft | 3 | Paper Feed Encoder Sensor |

| 2 | Roll Paper Residual Amount Encoder Sensor | 4 | Paper Feed Motor |

Roll Paper End Detection

There are two types of roll paper: One whose edge is fixed to the core and one whose edge is not.

- Fixed type (paper which cannot be separated from the core)

- Detection during transportation

When a fixed type of paper is used, the voltage applied to the sub scan motor increases rapidly when paper ends. The machine decides that paper ended when the voltage applied to the sub scan motor exceeds the threshold for a specified period or a specified number of transportations. The threshold voltage can be configured using SP1-954-001. The time can be configured using SP1-954-002. The number of transportations can be configured using SP1-954-008. - Detection during registration roller HOLD operation

When roll paper ends, the paper between the paper feed roller and the registration roller becomes tense. When pressure is applied to the registration roller at this point in order to hold the roll paper, the voltage applied to the sub scan motor increases. The machine decides that paper ended when the voltage applied to the sub scan motor exceeds the threshold while pressure is applied to the registration roller. The threshold voltage for the sub scan motor during registration roller HOLD operation can be configured using SP1-954-003 to 006. - Detection through measurement of the roll diameter

When roll paper ends, the roll core holder shaft does not rotate and the roll diameter calculated by the roll paper residual amount encoder becomes large. The machine decides that paper ended when the calculated roll diameter is 750 mm or larger twice in a row.

- Detection during transportation

- Unfixed type

The machine decides that paper ended when the trailing edge of the paper passes the front registration sensor.

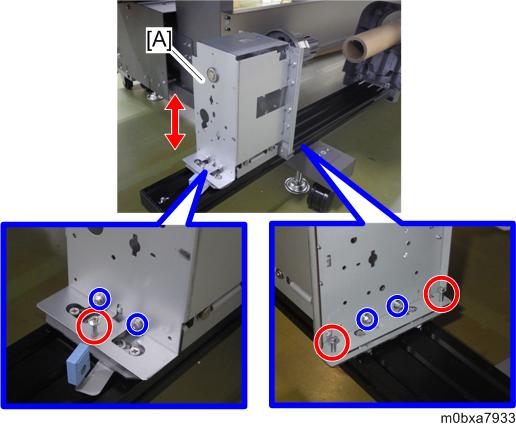

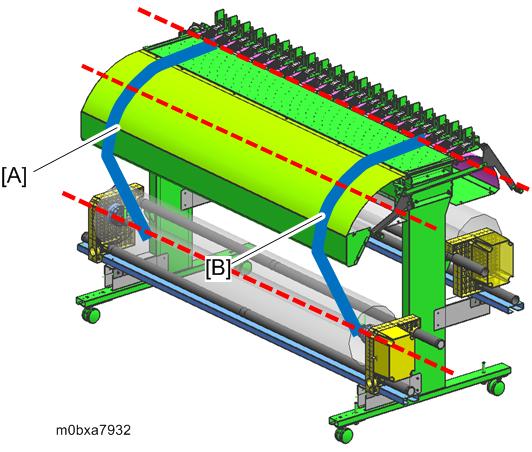

Skew adjustment mechanism

When installing the machine, you must manually adjust the height of each roll holder and adjust the levelness of the roll feed/transport/winding unit. (See Main Machine Installation > Paper Feed / Roll-up Alignment Adjustment.) Doing this ensures that the paper length is the same at both left and right edges [A] [B] of roll paper, preventing paper skew.

The height of the roll holder can be changed by adjusting the three screws in red circles with the four screws in blue circles loosened. Tightening the screw in red circles lifts up the bracket [A] which moves the roll holder up. Loosening the screw in red circles lowers down the bracket [A] which moves the roll holder down.