Component Layout

The flushing cartridge supplies cleaning liquid to the web during web wiping.

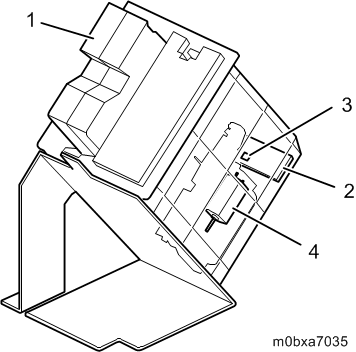

| No. | Name | No. | Name |

|---|---|---|---|

| 1 | Flushing Cartridge | 3 | ID Chip |

| 2 | Cleaning Liquid Set Sensor | 4 | Maintenance Unit Cleaning Liquid Supply Motor |

Cleaning Liquid Supply Mechanism

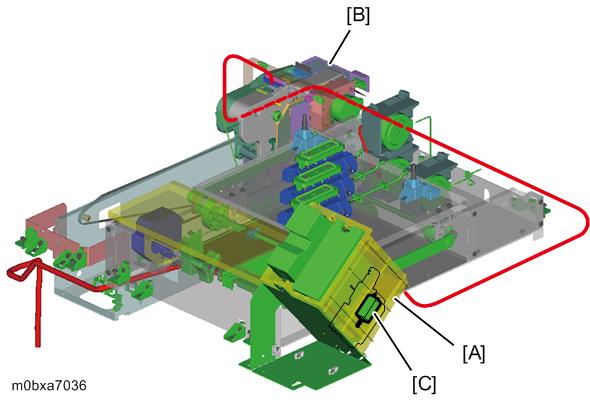

The supply of cleaning liquid from the flushing cartridge [A] to the web [B] is driven by the maintenance unit cleaning liquid supply motor [C].

An ID chip is attached to the bottom of the flushing cartridge. The ID chip stores information including new/used detection, lot number and amount of remaining cleaning liquid.

Set detection of the flushing cartridge is done when the cleaning liquid set sensor detects the ID chip.

Cleaning Liquid Near End/ Cleaning Liquid End

Cleaning liquid consumption is recorded by the software. The machines determines cleaning liquid near end/cleaning liquid end when the remaining amount is below the threshold.

Cleaning liquid near end

The machine displays cleaning liquid near end on the operation panel when the remaining cleaning liquid is below the threshold configured in SP2-256-010.SP No. Name Default Range SP2-256-010 Ink Near End Threshold: Residual Qty. Ratio Cleaning Liquid 20% 0 - 80 % Cleaning liquid end

When the remaining cleaning liquid is below the threshold configured in SP2-263-001, the machine detects cleaning liquid end. After cleaning liquid end is detected, the machine stops the current maintenance operation. "Cleaning liquid end" is written in the ID chip of the flushing cartridge and the cartridge can no longer be used.SP No. Name Default Range SP2-263-001 Ink End Threshold: Residual Qty. Ratio Cleaning liquid 5% 0 - 80 %